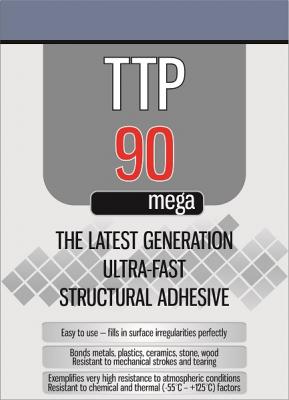

mega TTP-90, is the latest generation ultra-fast adhesive based on methacrylate, of high viscosity, cured at low temperatures and in thick layers. Strong adhesion properties and high viscosity of the adhesive also allow adhesive bonding on vertical surfaces. mega TTP-90 features perfect adhesion to thermohardened composites (SMC, BMC, RTM), fibre glass composites (CFRP), thermoplastic plastics, metals, (including non-ferrous and coated metals). Additionally, it may be used for the adhesive bonding of wood, concrete and many other materials and their combinations. Adhesive bonding established with the use of mega TTP-90 is characterised by high resistance to: vibrations, mechanical strokes, UV radiation, water, salt solutions, acids, lyes, etc. mega TTP-90 in installations caters for maximum equilibrium between mechanical force and resistance to influences, and at the same time it is easy and fast to use.

USAGE

Apply directly onto one of the bonded surfaces. In order to secure maximum bonding strength, the surfaces must be covered within a specified preparation time. All activities during adhesive bonding, positioning and fixing should be carried out within the preparation time. Movement of the bonded parts of the surfaces after the fixation time may cause the established bond to be less secure than usual. The right bond is guaranteed, when the adhesive is used at 18—26°C. Temperatures below 18°C slow down the process of adhesion, and above 26°C increase the curing speed.

mega TTP-90 is available in a double cartridge. In order to apply the adhesive correctly, a mixing tip and gun applicator should be used. A gun applicator facilitates the right application of adhesive onto the bonded surfaces.

Note: if the adhesive is applied with pauses lasting more than 2 minutes, the mixing tip should be replaced.

* Type in the captcha |

|

| |